- Zenith Flooring

- Jun 30, 2023

- Blog

- 0 Comments

Laser Screed technology considerably improves the speed and precision of concrete floor constructions meeting global standards (FM2 as per TR34), saving our clients time and money.

Our primary goal is to set new benchmarks for quality in concrete flooring by introducing cutting-edge technologies. Laser Screed technology assists us in this endeavour, says Ritesh Jain, Director of Zenith Flooring Services Pvt. Ltd.

How has your company revolutionised the flooring industry and set new standards for excellence?

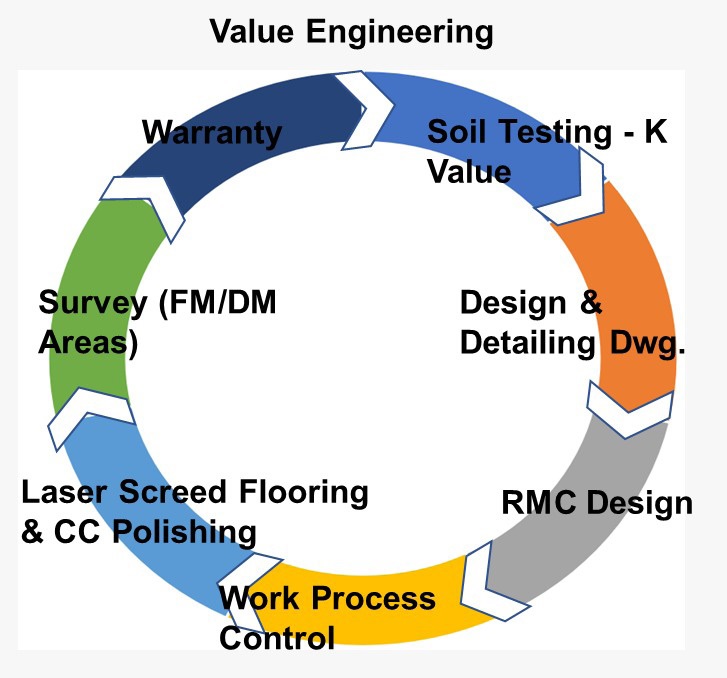

As the director of Laser Screed Concrete flooring company, I’m proud to say that we are setting new standards for excellence with our value engineering approach. Our company has been at the forefront of introducing cutting-edge technology and innovative techniques to enhance the efficiency, quality, and overall performance of concrete SOG flooring.

ZFS provides tailor-made, end-to-end solutions for Industrial and warehousing floors, making use of state-of-the-art Laser Screed Flooring machines from Somero USA, as per Global Standards:

- Flooring solutions based on the application type (Warehouses, Distribution and Fulfilment Centers, Manufacturing Plant, and Cold storage).

- Various categories of warehouses (VNA – Wire/ Channel guided, Mobile Racking, High-bay ASRS).

- Industrial and Warehousing floors for various applications

- Jointed Floors (Saw-Cut Floor) and Jointless Floors (SFRC CC).

- Seamless floor.

- Floor Flatness and Levelness Surveying.

- Advanced load transfer system

- Diamond Plate Dowels and Steel Armour Joints.

- Inhouse Designing based on TR-34 4th Edition (UK Concrete Society).

- Detailing Drawings of Column Isolation, Wall Isolation, Tied Joints and Steel Armour Joints.

- Detailing of Auxiliary or additional reinforcement.

- Surface Treatment – 5/7-Step Concrete Polishing.

- 3rd Party Sub-base testing – Plate load Test for K Value & Light weight deflectometer (LWD) For Evd Value.

Can you elaborate on your flooring solutions’ advanced technologies and innovative techniques?

We have adopted Laser Screed technology, completely transforming concrete floors’ installation. This technology utilises laser-guided equipment to ensure precise levelling and flatness, eliminating the need for a manual interface and reducing human errors. By implementing Laser Screed technology, we have significantly enhanced the speed and accuracy of concrete floor installations, saving time and costs for our clients.

With Laser Screed technology, we delivered floors as per global standards like TR-34 4th Edition from The UK Concrete Society, meeting surface regularity requirements in flatness and levelness tolerances as per modern MHE requirements. The precise control provided by our equipment ensures a smooth, seamless, and durable flooring surface, enhancing the aesthetics and functionality of the space.

To achieve this, a large pour methodology is adopted, where floors are laid in areas of up to 900 to 1500 M2 between construction joints in a continuous operation. The following day, the floor is sawn into panels on a 6m grid to relieve drying shrinkage stresses. This type of floor construction is typically reinforced with a single layer of steel deformed bar mesh at the bottom of the slab or uses Steel fibres (SFRC Concrete).

This includes advanced load transfer systems like Diamond plate dowels at the construction joints. A diamond plate dowel system is a load transfer device used at construction joints in concrete slabs. It consists of a series of diamond-shaped metal plates with raised edges that are inserted into the concrete on either side of the joint. The plates are typically designed to resist bending and shear forces.

Also, Steel armour joints are used at the construction joint to protect the arries/edges of the construction joint. Steel armour joints, also known as armour joint systems, are used in concrete construction to protect the edges of the joint from damage due to heavy loads or traffic. The armour joint system consists of two steel plates anchored to each side of the joint using studs. The steel plates are designed to protect the edges of the joint from spalling or other damage caused by heavy loads or traffic.

Floor aesthetics are taken care of by adopting surface treatment making use of 5 to 7 steps of concrete polishing. Surface treatment with a concrete polishing process provides a highly durable and attractive finish to concrete floors. The process involves using specialised equipment to mechanically polish the surface of the concrete and applying various treatments to enhance its strength and durability.

This basically involves the following steps:

Grinding – The first step is to use a coarse metal/ resin abrasive to grind the surface of the concrete to remove any roughness, blemishes, or surface contaminants.

Honing – The second step is to use progressively finer resin abrasives to smooth out the surface of the concrete and achieve the desired level of sheen and shine.

Densification – The third step involves the application of a concrete densifier. This liquid chemical penetrates the surface of the concrete and reacts with the minerals to create a harder, more durable surface.

Polishing – The fourth step is to use finer resin abrasives to polish the concrete to a desired shine/Gloss.

By adopting a concrete polishing process, the finished floor has a smooth, reflective surface that is easy to clean and maintain. It is also more resistant to scratches, stains, and abrasions than a concrete surface.

Can you share compelling success stories or testimonials that demonstrate the transformative impact of your flooring solutions?

The list is long, but to mention, we have completed Multilevel Cargo Building Project (G+1) At Cargo Terminal T2, IGI Delhi Airport (Area 18000. M2) for Shristi Cargo Warehouse Pvt Ltd.

For more details, contact:

Zenith Flooring Services Pvt Ltd

(With a fleet of 4 Somero USA Laser Screed Machines)

C-505, 5th Floor, Nirvana Courtyard, Nirvana Country, Sector 50, Gurugram – 122018, Haryana

Call: 8810508596

Email: ritesh@zenithflooring.com