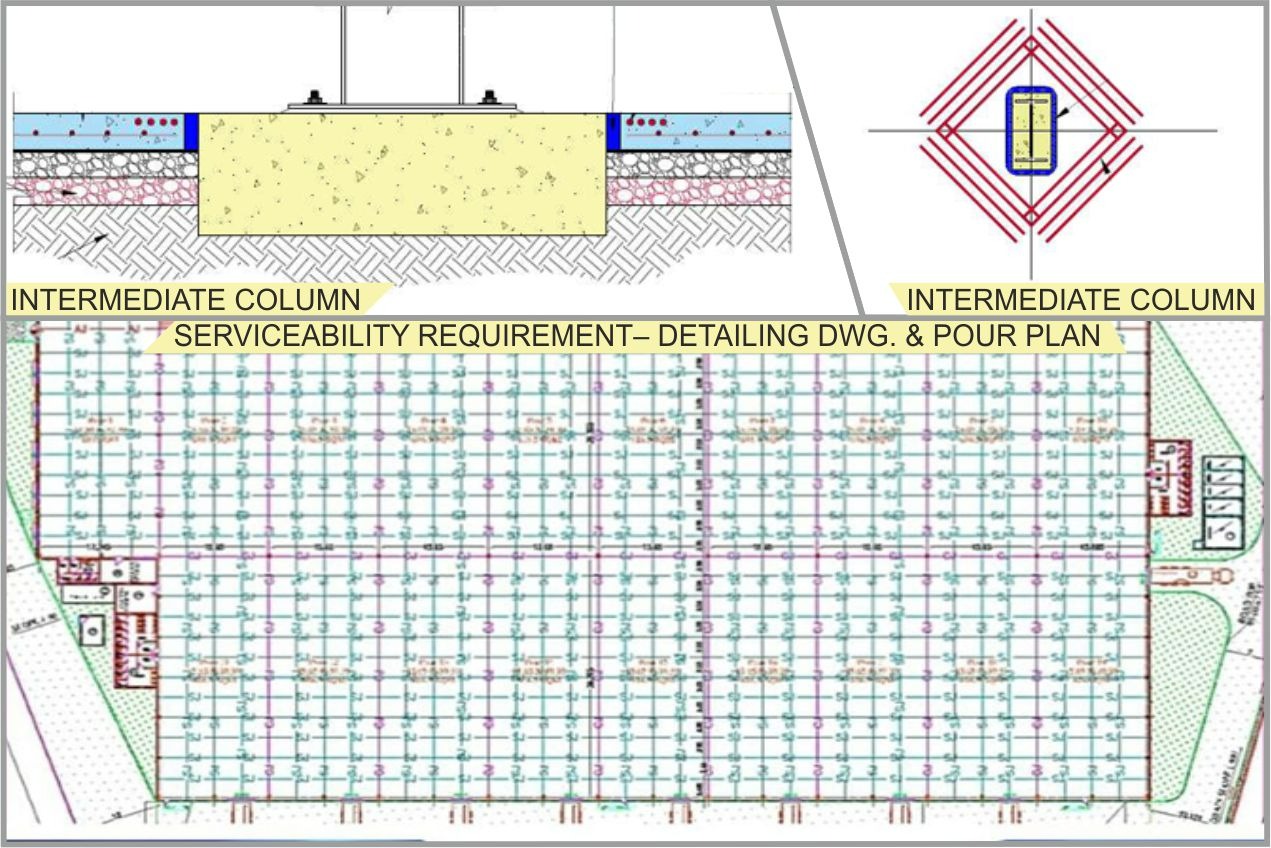

Detailing Drawing and Pour Plan of floors are provide by us. We provide detailed drawings of floor Joints including layout plan and sectional elevations as per the functional requirement of the flooring facility. Large areas of up to several thousand square meters have been laid by us in a continuous operation.

Floor levels are controlled both manually using a target staff in conjunction with a laser level transmitter and by making use of laser-guided spreading machines S-158C Somero USA, adopting a Large area construction method. The pour plan is submitted by us for every pour which describes all activities during the construction process. The floor is poured into bays. The proposed pouring schedules are also submitted by us for approval before any concrete is laid.

Shrinkage of the concrete is inevitable and any restraint to that shrinkage has the potential to cause cracking. To reduce the risk of cracking, all steps must be taken to reduce both the potential shrinkage and potential restraint through detailed drawing analysis. We come up with mixed designs and placement strategies that would be a perfect fit for client requirements. Restraint to shrinkage can be minimised by careful attention to isolation details around columns and other intrusions, by the use of sawn-induced joints and by minimising sub-base restraint.

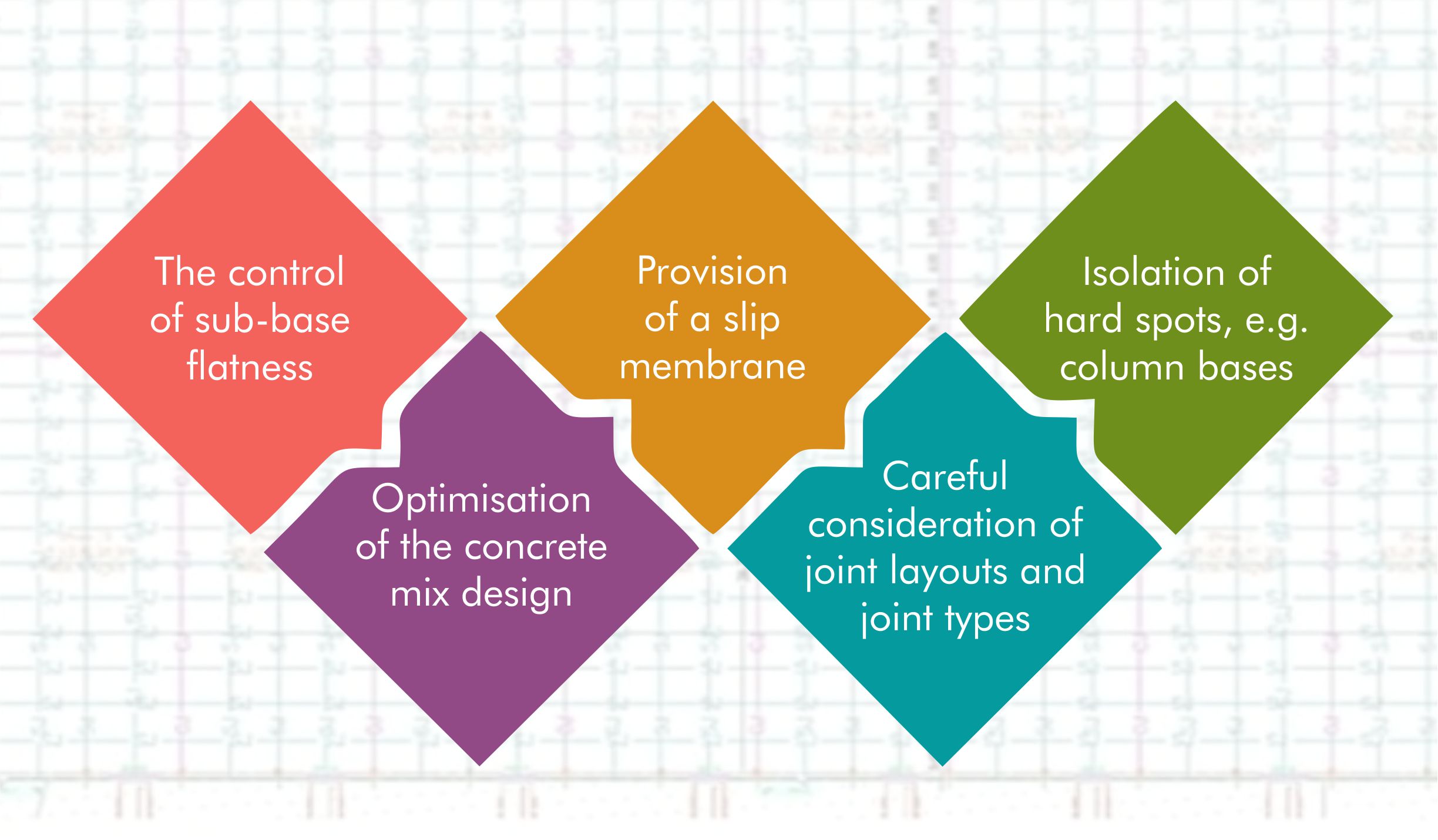

Our drawings detail approach minimises the risk of shrinkage-induced cracking by reducing the restraint to movement by combining the following: